Emi Bulkhead Feedthrus

SEEPA - SE

- REPLACES STUFFING TUBE ASSEMBLIES

- PROVIDES RELIABLE 360-DEGREEGROUNDING OF SHIELDED CABLES

- COMPLETELY WEATHER SEALED

- MOUNTS DIRECTLY TO DECK OR BULKHEAD

- SIMPLE SHIPBOARD INSTALLATION REQUIRES NO WELDING OR SPECIAL TOOLS

- KIT CONTAINS EVERYTHING NEEDED FOR A COMPLETE WATERTIGHT ASSEMBLY

For more information and sizes, click here

FIELD-PROVEN SEEPA EFFECTIVENESS AND RELIABILITY

RECOMMENDED BY NAVSEA FOR CABLE INSTALLATIONS INTO SHIELDED COMPARTMENTS

SEEPA - SE SIZE CODES

|

SIZE CODE

|

PENETRATION DIAMETER

|

MAX OD OF CABLE

|

MIN OD OF SHIELD

|

|

00

01 02 03 04 05 06 07 08 09 10 11 12 |

15/16

- 1.0 15/16 - 1.0 1.0 - 1-1/16 1-7/16 - 1-1/2 1-1/2 - 1-9/16 1-11/16 - 1-3/4 1-3/4 - 1-13/64 2-1/8 - 2-1/4 2-5/16 - 2-3/82 2-5/8 - 2-3/4 2-7/8 - 3.0 3.0 - 3-1/8 3-3/8 - 3-1/2 |

.300

.400 .500 .750 .840 .950 1.175 1.400 1.625 1.875 2.000 2.190 2.500 |

.125

.200 .250 .400 .500 .625 .800 1.000 1.250 1.500 1.625 1.750 2.000 |

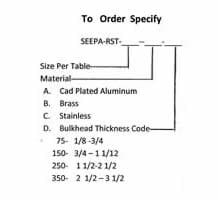

SEEPA - RST

EMPRESS II PROVEN SEEPA EFFECTIVENESS AND RELIABILITY

- MEETS THE REQUIREMENTS OF MIL-STD-1310

- REPLACES PLASTIC STUFFING TUBES

- MOUNTS DIRECTLY TO PANEL OR BULKHEAD PENETRATIONS

- PROVIDES RELIABLE 360° GROUNDING ABOVE OR BELOW DECK

- DOUBLE SPRING DESIGN INCREASES PERFORMANCE

- FIRE PROOF HEAT-SHRINKABLE WEATHER SEAL

- STANDARD MATERIALS TO MEET ANY APPLICATION

Each Seepa Kit Includes

- Complete grounding adapter of the specified size and style

- The required amount of A-A-59313 anti-seize compound

- Abrasive cleaning strip

- Heat shrinkable weather seal boot

- Simple installation instruction

RST SIZE CODES

|

SIZE

|

MAX OD OF CABLE

|

MIN OD OF SHIELD

|

|

1

2 3 4 5 6 7 8 9 10 11 12 |

.400

.500 .750 .840 .950 1.175 1.400 1.625 1.875 2.000 2.190 2.500 |

.200

.250 .400 .500 .625 .800 1.000 1.250 1.500 1.625 1.750 2.000 |

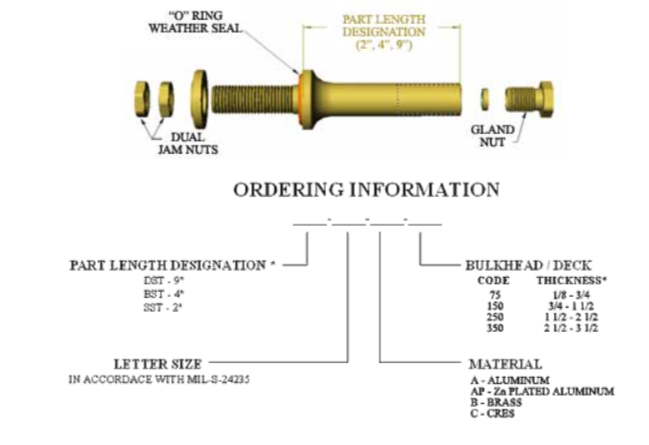

Bolt-On Stuffing Tube

Bolt On Stuffing Tube

- –Alternative to welded applications, when hot work should be avoided (space has already been painted)

- –Used in non-welded applications, including Composites or non-metal interfaces

- –Developed for MHC (mine hunters) and expanded application for PDA, PSA, and backfit

We have the ability to support unique configurations, sizes, lengths, etc., without adding a cost for design (NRE)

- –How can you best support your need for materials in a timely manner?

- –We want to be part of the solution and committed to CNC Excellence

Note: This product does not provide a shield termination independently, but may be used in conjunction with SEEPA technology to achieve the desired ground path.